5.4 Nepal: An Efficient Retrofit Approach Can Meet Performance Objectives While Reducing Emissions

| Location | Central and western Nepal |

|---|---|

| Context | Post-disaster (2015 Gorkha earthquakes) |

| Number of Houses Analyzed | 91 retrofit, 1 new construction |

| Hazards | Earthquake |

| Building Type | 1 or 2 story plus attic, stone with mud mortar or timber frame, lightweight roof |

| Intervention Scope | Repair and retrofit |

| Performance Level | Life safety |

Program Details

In April and May 2015, Nepal was hit by two consecutive earthquakes, during which more than one million houses collapsed or incurred damages, mostly in rural and hard-to-reach areas of the Himalayan region. A comprehensive survey conducted by the Central Bureau of Statistics after the earthquakes found that only 29 percent of affected homes needed to be reconstructed, and the remaining 71 percent needed to be retrofitted.

The government announced a homeowner-driven reconstruction program, with two subsidy options available to homeowners, depending on the assessed damage level of their house: NPR 100,000 (USD 900) for repair and retrofitting, and NRP 300,000 (USD 2,700) for full construction of a new house. In response, Build Change developed one type design and adapted two government-approved designs for retrofitting: one for stone masonry and mud mortar houses, and one for timber houses. These designs were officially approved by the government in 2017, and subsequently Build Change led and participated in a diverse range of programs focused on scaling home repair and retrofitting in the country.

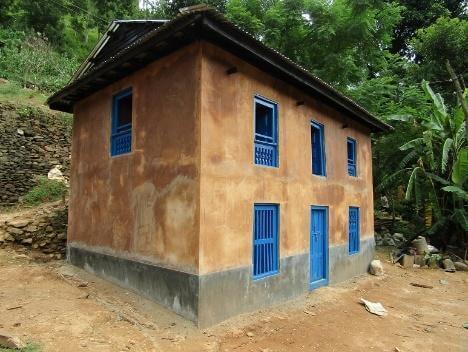

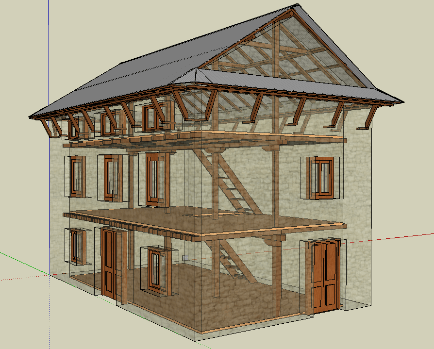

Throughout the earthquake-affected region, the materials and construction methods used for existing houses are very similar. Houses are typically two stories high, with an additional half story attic space. The walls are thick, unreinforced stone masonry with mud-based mortar. The inter-story floors are timber, and the pitched gable roof is framed with timber and covered with metal sheets or ceramic tiles.

Stone masonry houses are similar in size and configuration and the most common typology in rural Nepal

A typical stone masonry in mud mortar house in Eklephat village in Nepal before (left) and after (center) being retrofitted. (Right) 3D structural model of a typical stone masonry house in rural Nepal.

The houses analyzed for this study were retrofitted as part of the National Reconstruction Authority’s national reconstruction program. The equivalent new construction baseline is taken from the government’s approved standard design catalogs for resilient new construction of stone houses with cement mortar.

Findings

Overall, home improvements in Nepal save 70 percent of the emissions of equivalent new construction. On average, improving existing homes in Nepal for earthquake damage repair and strengthening saves 15 metric tons of carbon dioxide per house (0.2 tons per square meter).

The improvement program in Nepal demonstrates the impact of existing building typology on embodied carbon emissions. On average, strengthening a timber house had lower embodied carbon than a masonry home.

Housing improvement programs have many more constraints than new construction. One key constraint is that the materials of the existing building often dictate what materials can be used for the strengthening design. For example, an unreinforced masonry building typically cannot be strengthened using only timber and instead reinforced concrete is usually required.

The topography of Nepal and remoteness of many communities affected by the earthquake added another layer of constraints. In some cases, access to construction materials was difficult, and with limited financial subsidies available to homeowners, each material had to be transported from the market centers, which were sometimes located at a distance from the homes. But from an embodied carbon perspective, these constraints were all benefits as they forced the retrofit design to minimize imported, high carbon materials and maximize local, natural materials such as stone and mud.

The Nepal program also demonstrates how the strengthening design can impact the emission savings. For stone masonry houses with mud mortar, two different strengthening techniques were used, referred to as “strong back” and “splint and bandage.” On average, the emissions savings from adopting the strong back design approach are almost 40 percent higher than for the splint and bandage approach. Both approaches are effective at reducing the vulnerability of the house to earthquakes, with comparable financial costs.[1]

Figure 18: Embodied Carbon by Existing Housing Type and Strengthening Design in Nepal

SMM = stone with mud mortar

References

- Giordano, Nicola, et al. “Financial assessment of incremental seismic retrofitting of Nepali stone-masonry buildings.” International Journal of Disaster Risk Reduction 60, (2021). https://doi.org/10.1016/j.ijdrr.2021.102297 ↩